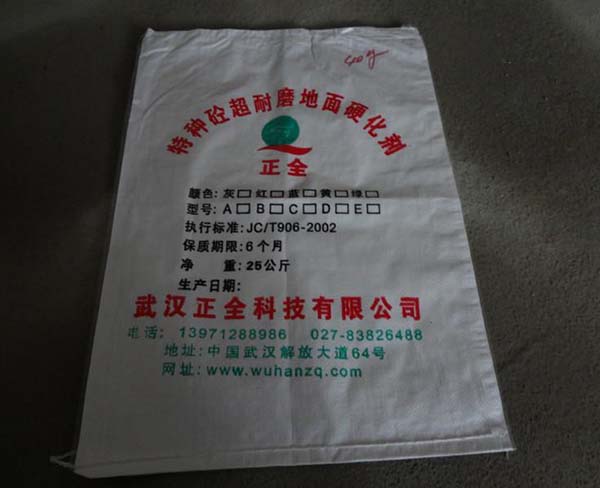

Analysis of the Production Process of Woven Bags in Hefei

IV. Quality Control

Quality control in production encompasses the quality control of raw materials, quality control during the production process, and quality inspection of finished products, etc. It is necessary to establish a complete quality management system, conduct regular quality inspections, and ensure that product quality meets national standards and customer requirements. V. Environmental Protection Treatment: During the production process of woven bags in Hefei, waste gas, wastewater and solid waste are generated. Corresponding environmental protection measures need to be taken, such as waste gas treatment equipment, wastewater treatment facilities and waste residue recycling and utilization, to reduce pollution to the environment. Summary: The production process of woven bags in Hefei includes raw material selection, mold selection, production process, quality control and environmental protection treatment, etc. During the production process, it is necessary to strictly control the quality and environmental protection standards of each link to ensure product quality and environmental protection.